Learning about Lithics from the Knapper’s-Eye-View

The best way to learn flintknapping is to do it. The second best way is to see it in action from the knapper's perspective. This website will introduce you to stone tools and provide a sense of the knapper’s perspective and decision-making process. Photos and short videos show basic knapping techniques, including hard hammer percussion, soft hammer percussion, and pressure flaking. Through these examples, you can learn how to identify the processes that past people used to produce the lithic artifacts in the archaeological record. Go to the Learning Flintknapping page to find out more about how you can learn flintknapping.

Homo erectus, Homo habilis, and Australopithecines (such as Lucy) made stone tools. This does not mean that making stone tools is easy. Though the types of stone used in flintknapping fracture in predictable ways, controlling the way you strike a stone to produce a particular shape is a difficult skill to master. I hope that this website will help you appreciate the skills of our ancestors.

The Basics

Lithics are stone tools and the waste products of the tool-making process.

Debitage comprises the waste products from the tool-making process. (Debitage comes from the French word for trash.) The most common lithics in the archaeological record are debitage, not tools.

Flintknapping is the process of making stone tools.

The two main classes of lithic technology are flaked/chipped stone and groundstone. Flaked/chipped stone technology involves flaking stone through percussion or pressure. It is used to make tools such as knives, projectile points (spear and arrow points), scrapers, and drills. Groundstone technology involves shaping stone through abrading, polishing or pecking. It is used to make tools such as manos, metates, mortars, pestles, bowls, and axes.

Flaked/Chipped Stone Technology Basics

Good toolstone breaks in predictable ways in all directions. Flintknappers want homogenous toolstone with high silica content. Striking good toolstone produces conchoidal fracture, which looks like the growth rings of a bivalve.

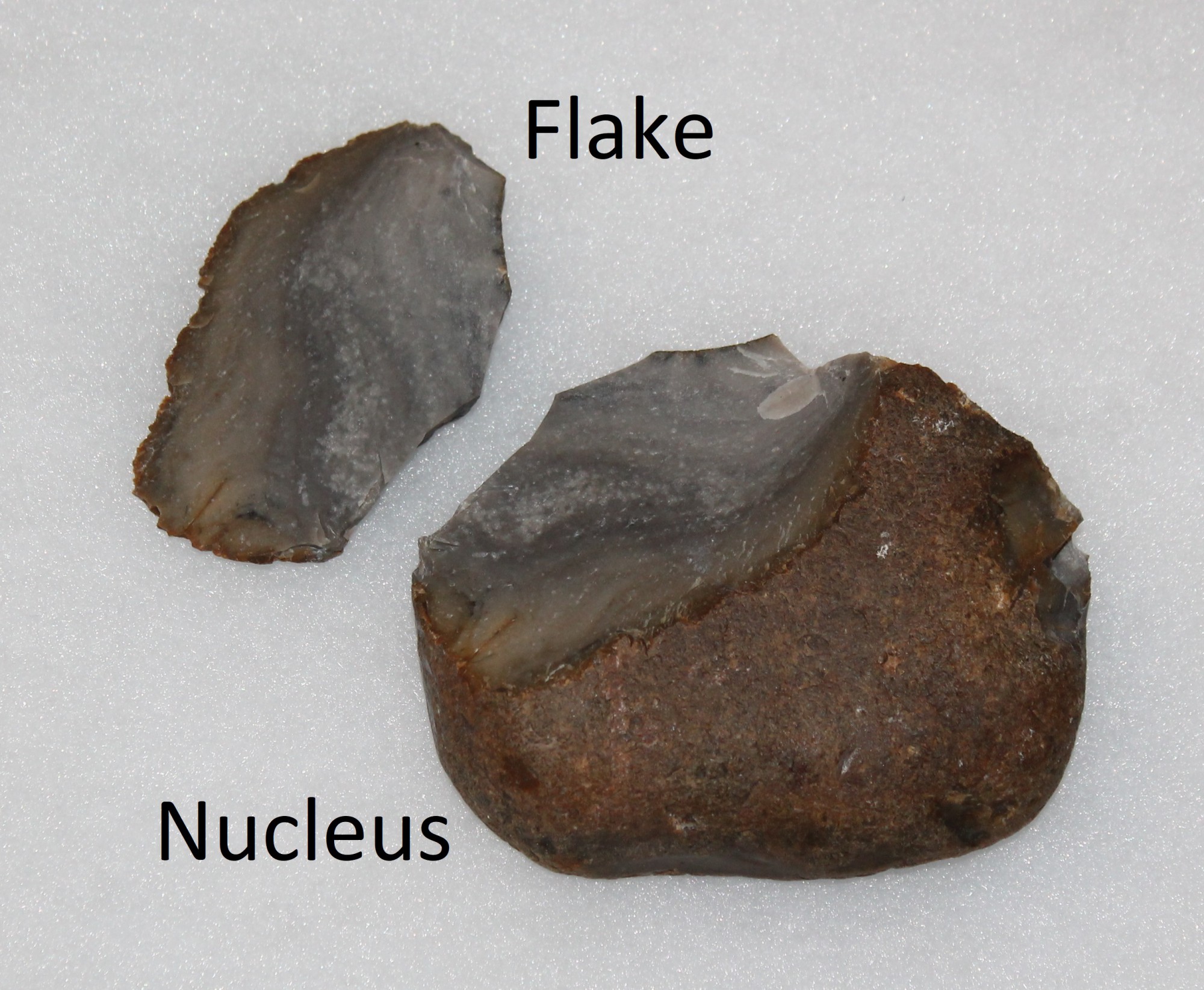

A flintknapper starts with a stone nucleus and removes flakes from the nucleus.

Flaked stone tools are often classified based the number of faces (sides) of the nucleus that were flaked.

Unifacial tools have flakes removed from one face.

Bifacial tools have flakes removed from both faces.

To understand how past people flintknapped stone tools, archaeologists recreate the chaîne opératoire: the operational sequence of making, using, and discarding tools. The step-by-step decisions include acquiring raw materials, making a tool, using the tool, and discarding the tool. Understanding these decisions helps us understand the lives of past people.