Flakes

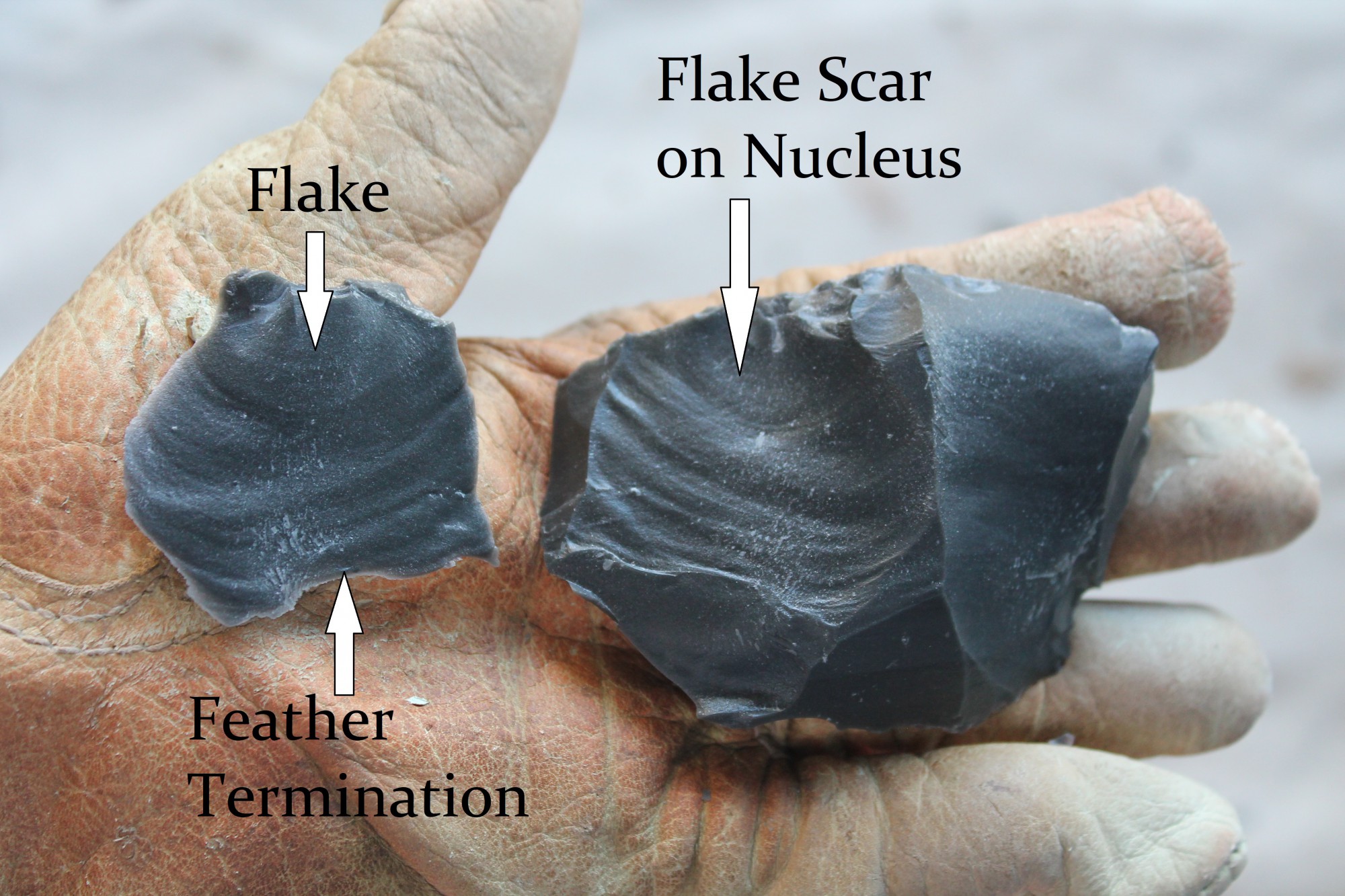

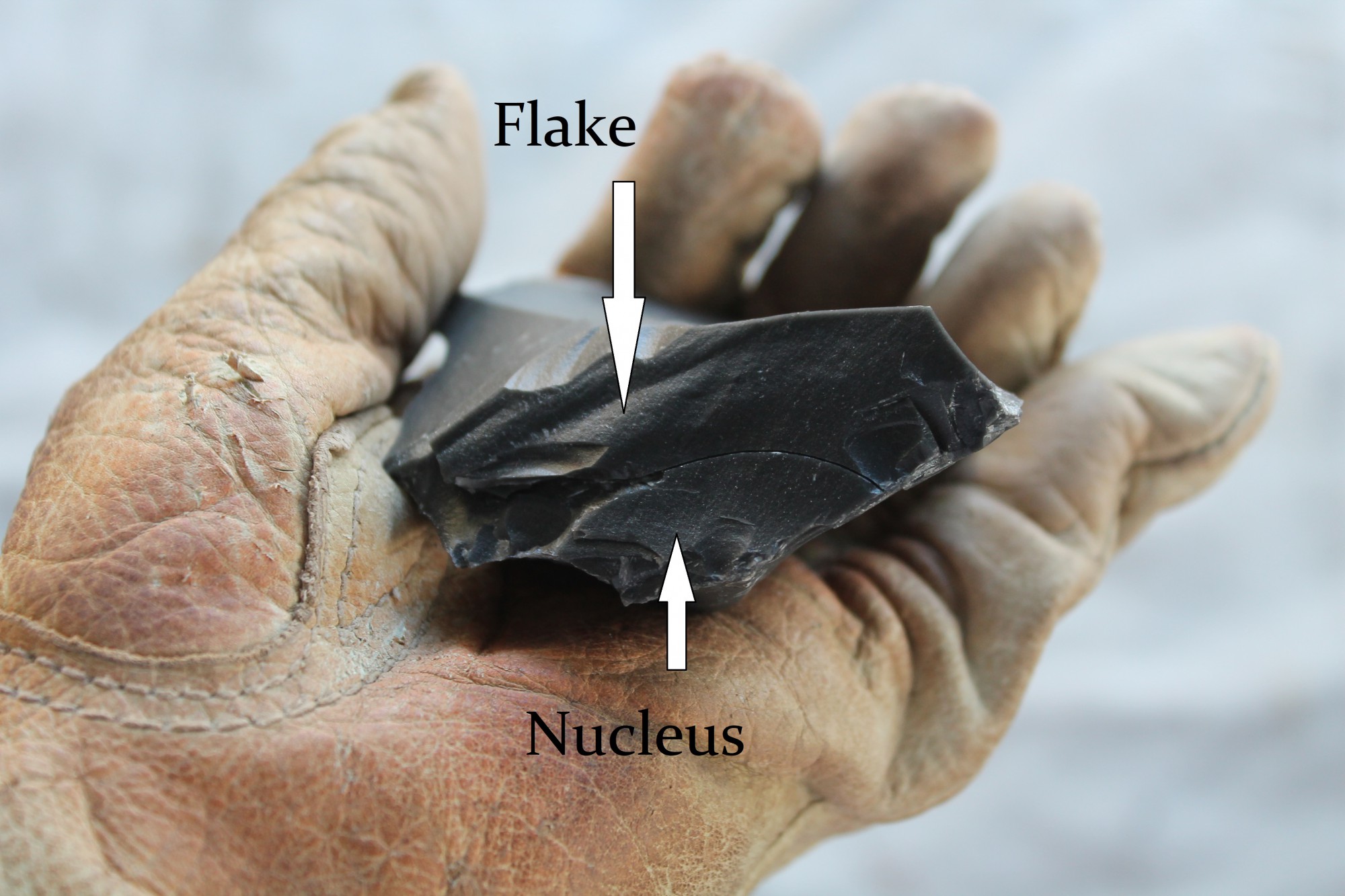

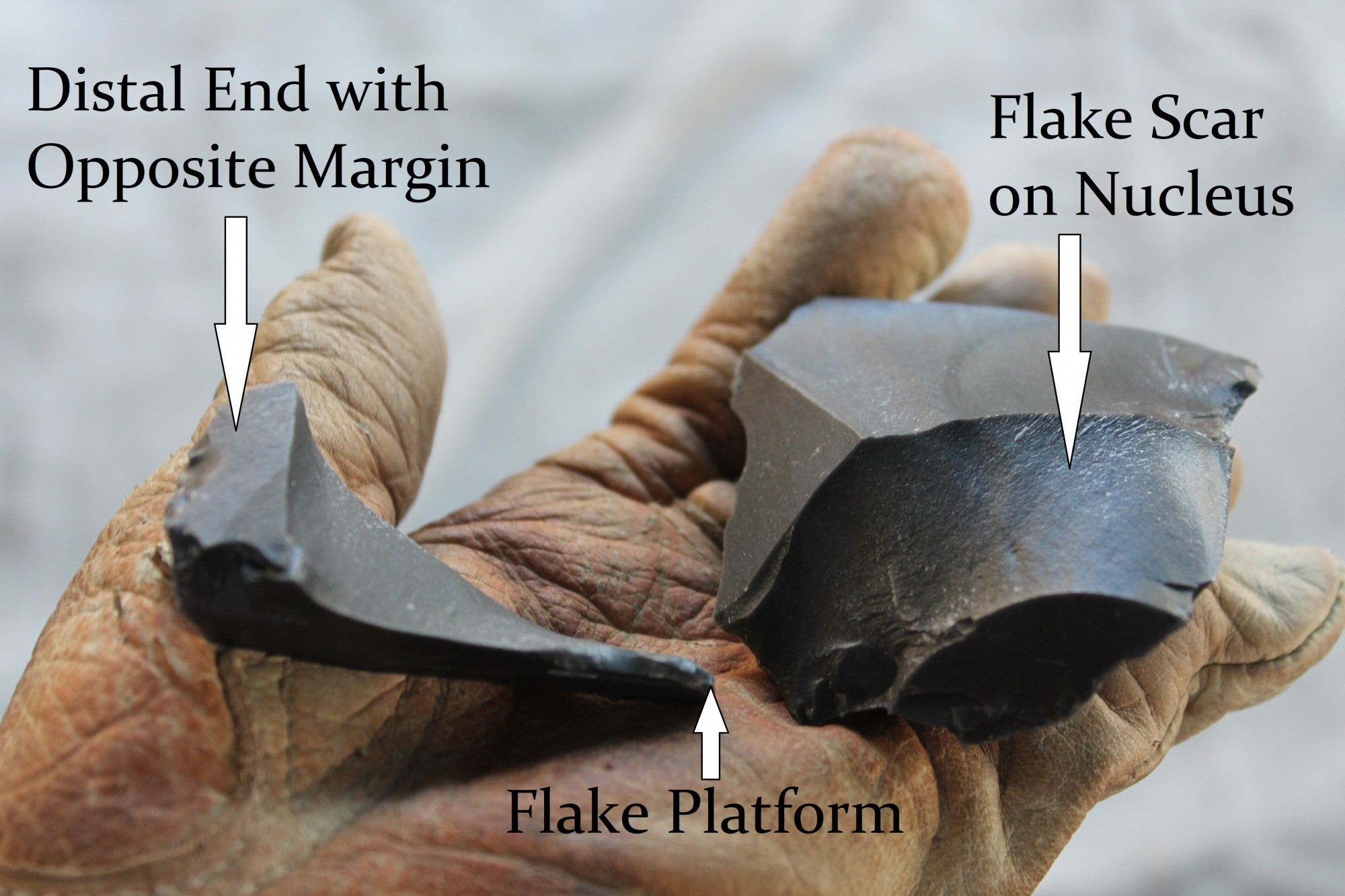

A flake is a section of stone removed from a nucleus through percussion or pressure. The platform is where the flake is struck from the nucleus (i.e., the spot where the percussive or pressure force is applied).

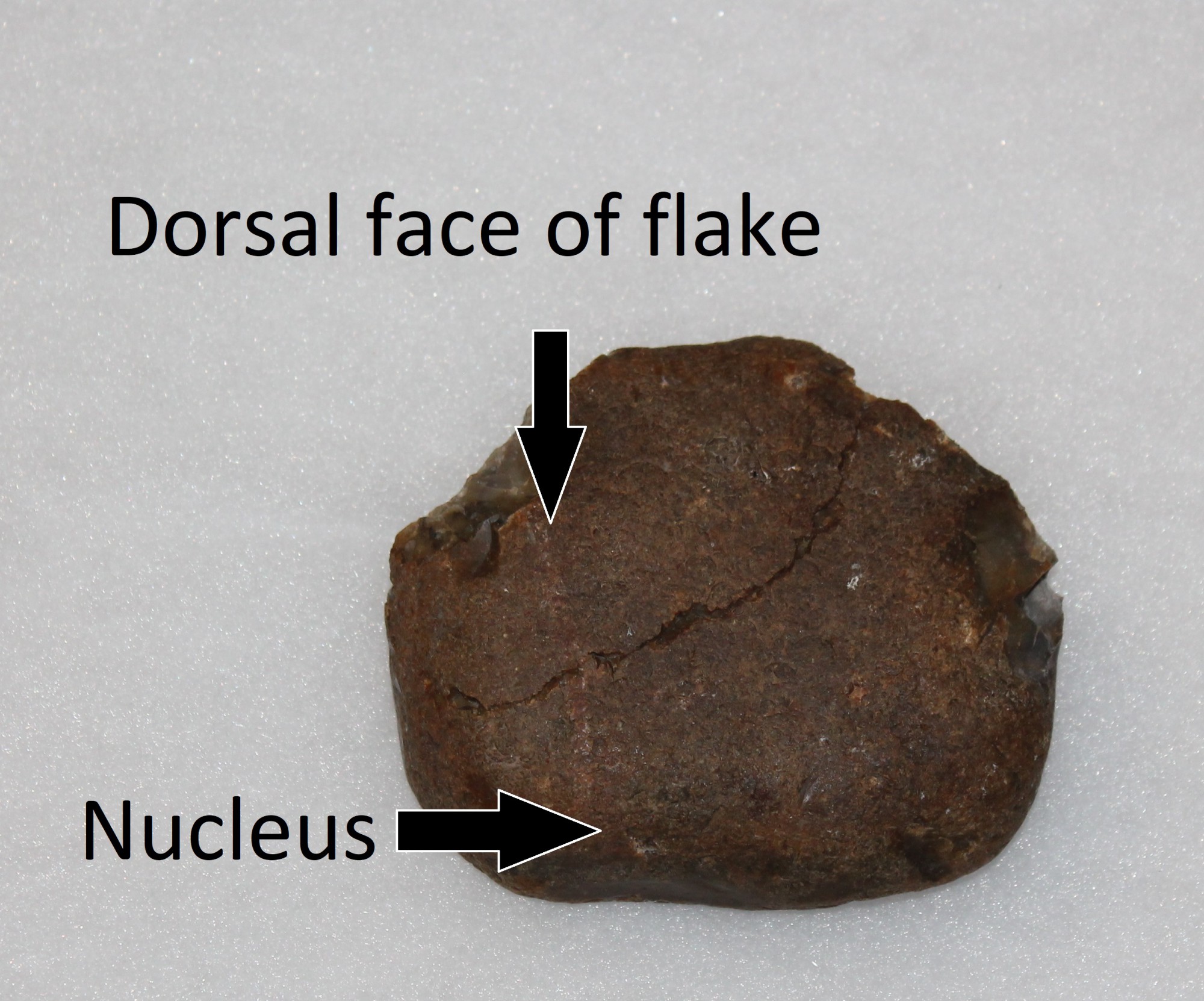

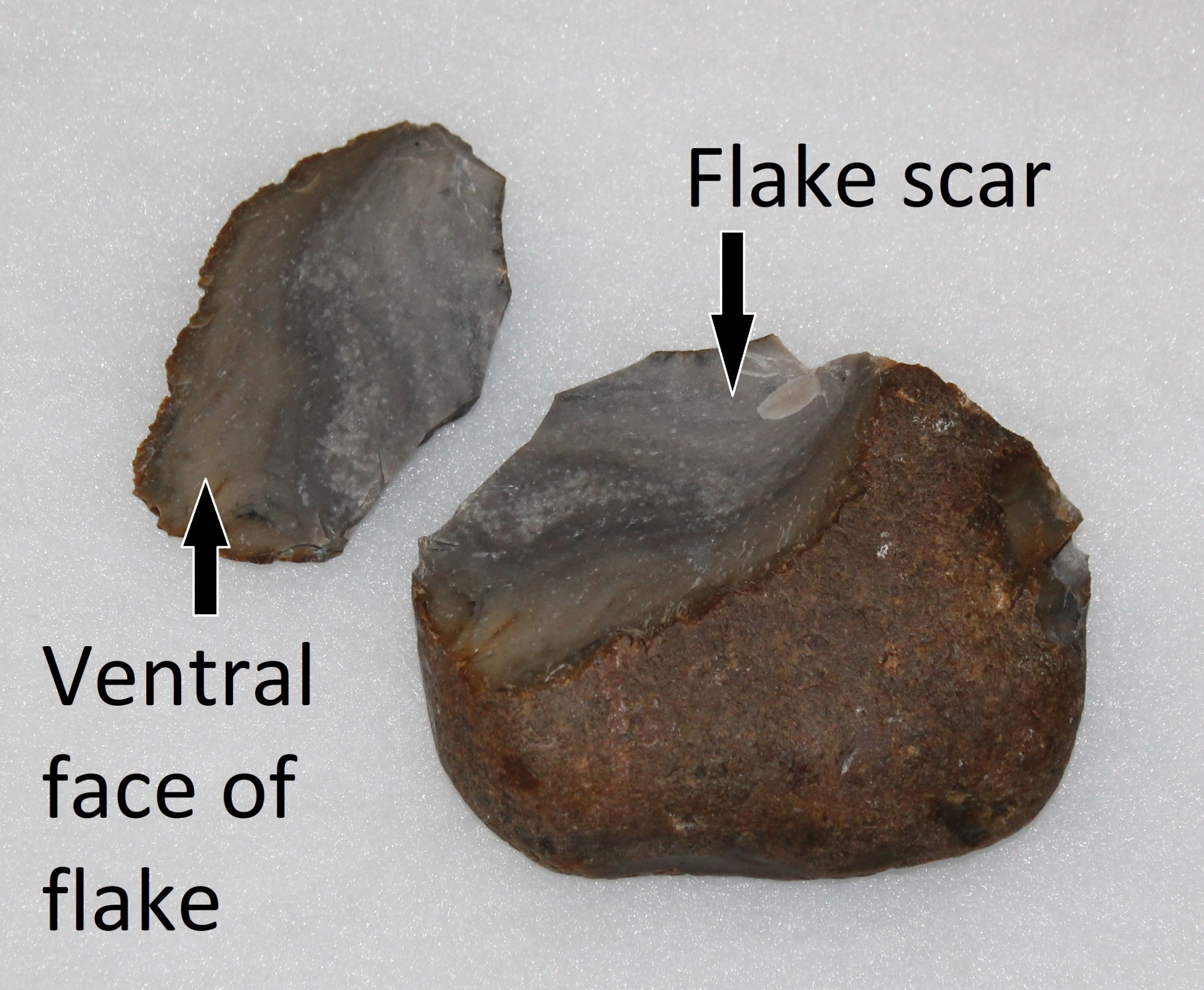

There are two faces (sides) of a flake that are best understood by refitting the flake into the nucleus as shown in the figures below:

- Dorsal Face: side that faces away from the nucleus

- Ventral Face: side that fits into the nucleus

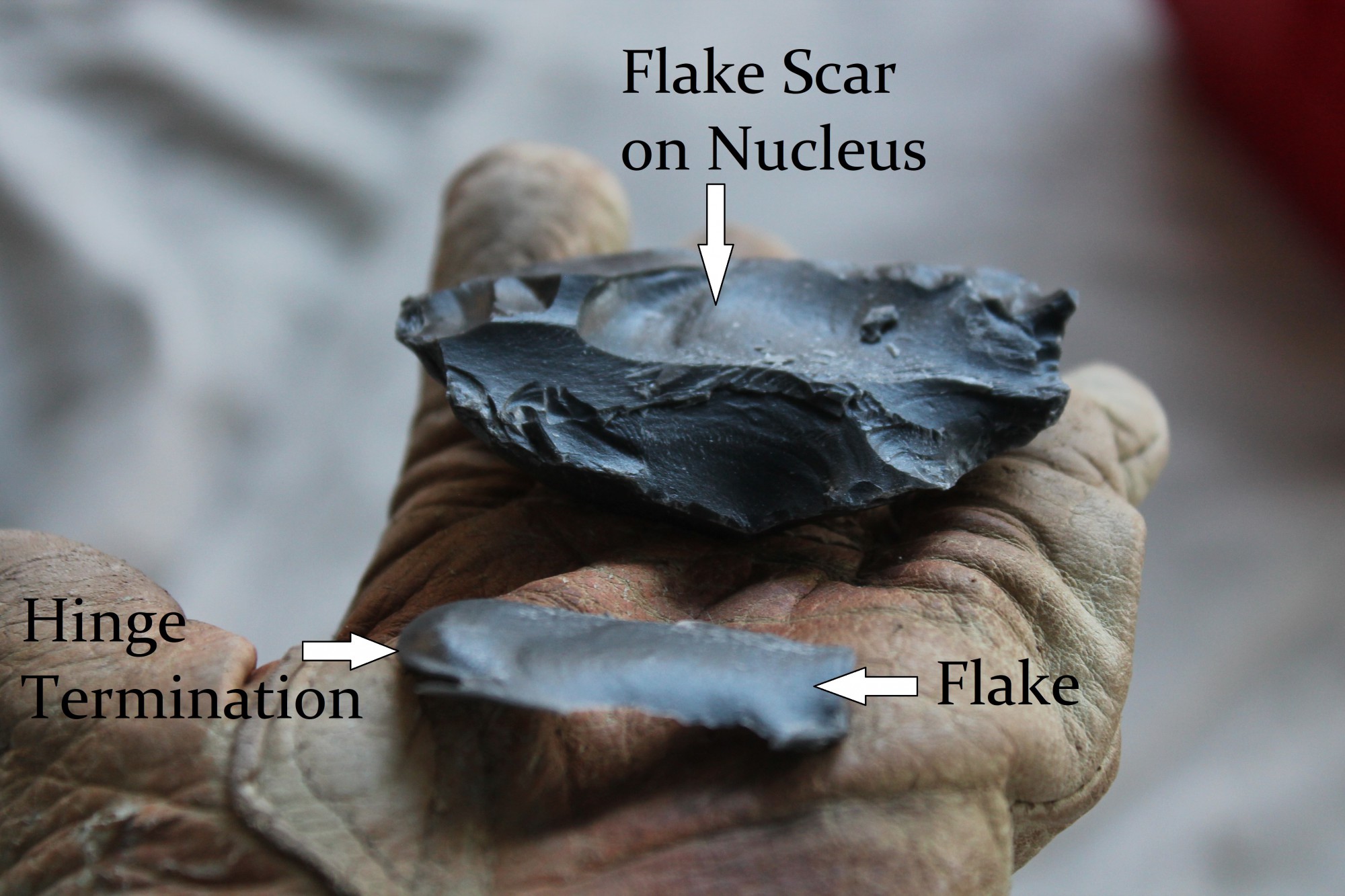

- Flake Scar: place on the nucleus where the flake refits

Principles of Fracture Mechanics

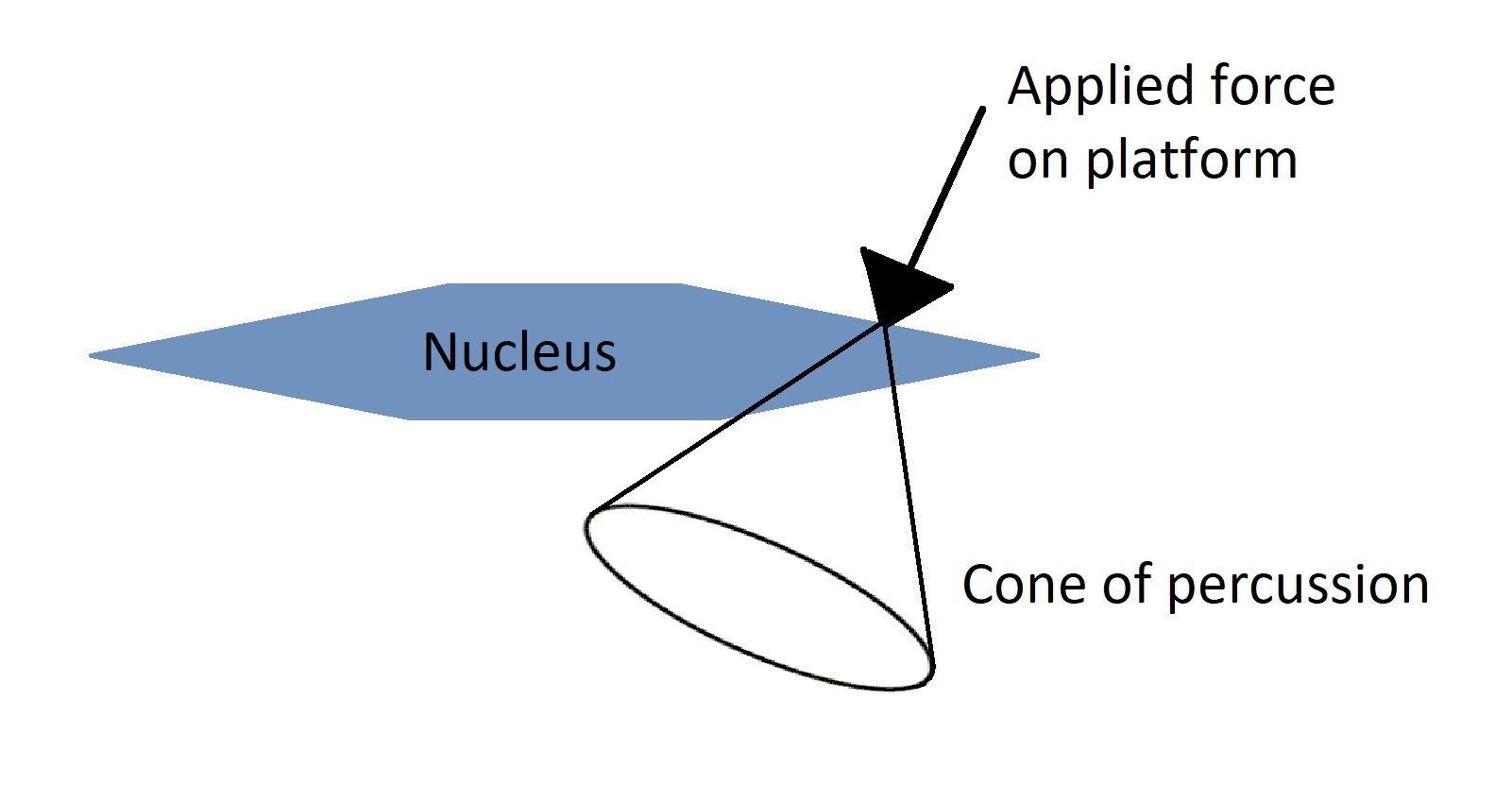

Good toolstone is isotropic, which means it fractures in the same, predictable way in all directions. When the knapper applies percussive force to the nucleus, the conchoidal fracture propagates in a cone from the point of impact. This cone of percussion is also known as the Hertzian Cone. The knapper controls the direction and size of the force to produce the intended flake.

Flake Characteristics

There are several characteristics of human-made flakes that distinguish them from "just a rock."

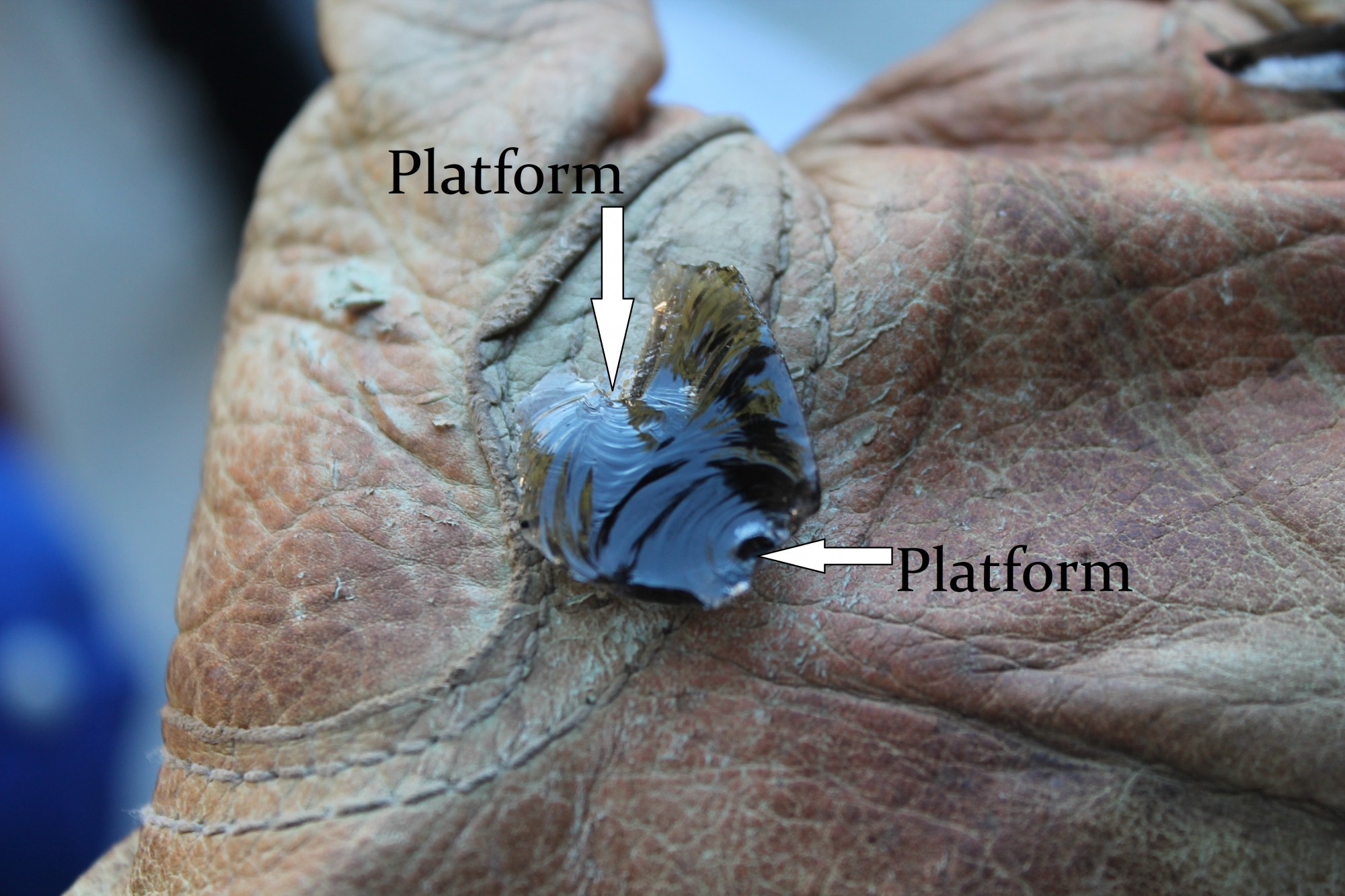

The platform is where the knapper applied percussive or pressure force to the nucleus to remove the flake.

The fissures/hackles are lines like a sunburst from the point of impact. They point to the platform.

Often removing a flake from the nucleus produces a secondary flake. The erraillure scar is the flake scar from this secondary flake. The errailure scar is close to the platform.

The bulb of percussion is a round mound just beneath the platform. It is part of the Hertzian cone.

The compression waves are ripples radiating from the point of impact on the platform much like ripples in a pond radiate out from the point where a stone hits the water.

We use these features to identify the proximal and distal ends of flakes to better understand the choices the knapper made. The knapper strikes the platform, which is the proximal end of the flake. The distal end is the termination of the flake opposite the platform.

Flake Terminations

Usually the knapper tries to strike the platform so that the termination feathers to a sharp edge. However, depending on the skill level and goals of the knapper, other terminations are possible.

Terminations

Feather Termination

The distal end of the flake thins to sharp edge. Usually the knapper wants a feather termination to make sharp tools.

Hinge Termination

The distal end of the flake is thick and rounded because the knapper did not strike the platform with enough force to feather out. Usually the knapper is disappointed to make a hinge termination because the flake isn't sharp and the flake scar makes it harder to strike flakes with feather terminations from the nucleus.

Step Termination

The distal end of the flake is thick and squared because the knapper did not strike the platform with enough force to feather out. Instead, the break abruptly veers up at distal end of flake. The square angles of the step that is left on the nucleus will cause step terminations in subsequent neighboring flakes, causing a big headache for the knapper.

Overshoot Termination

A flake with an overshoot termination extends across the nucleus and removes the margin (edge) opposite the platform. The knapper struck the platform with too much force to feather out. Some knappers intentionally strike overshoot flakes to make the nucleus more narrow.

Specialized Flakes

Knappers make different types of flakes depending on the raw materials they have and type of tool they want to create.

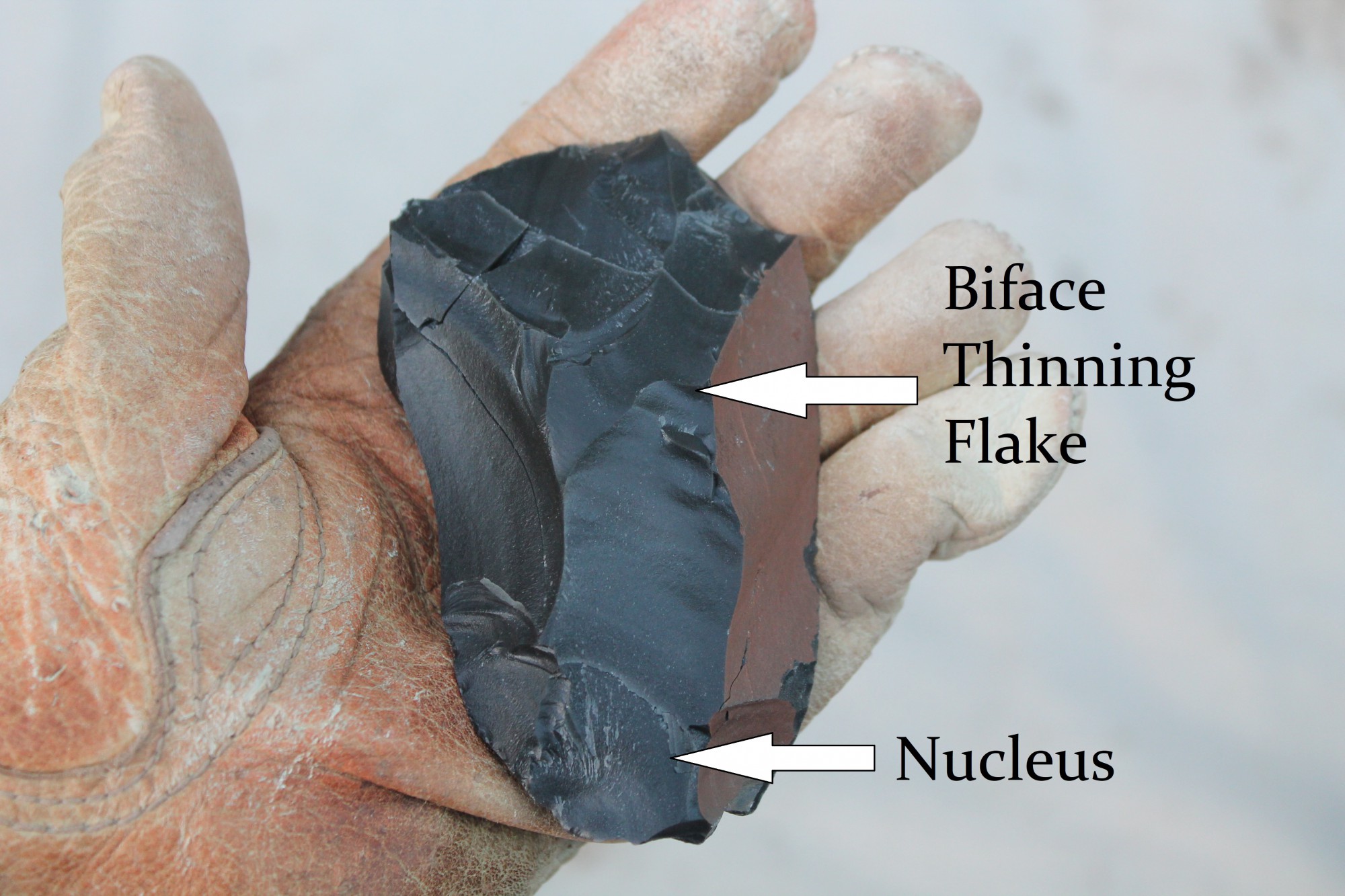

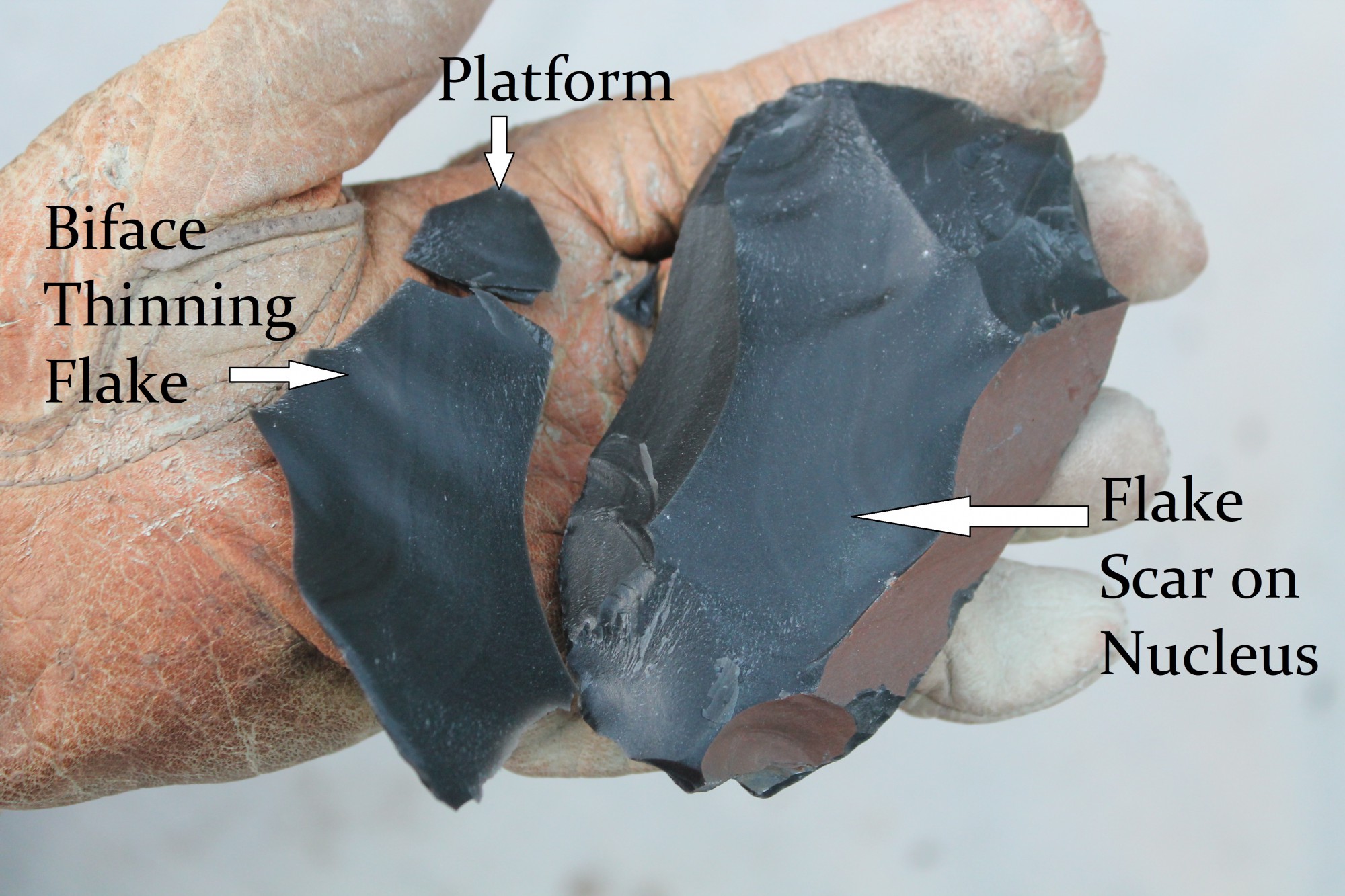

Biface Thinning Flake

A biface thinning flake crosses at least halfway across the nucleus. The knapper makes biface thinning flakes in order to transform the nucleus into a sharp, narrow biface.

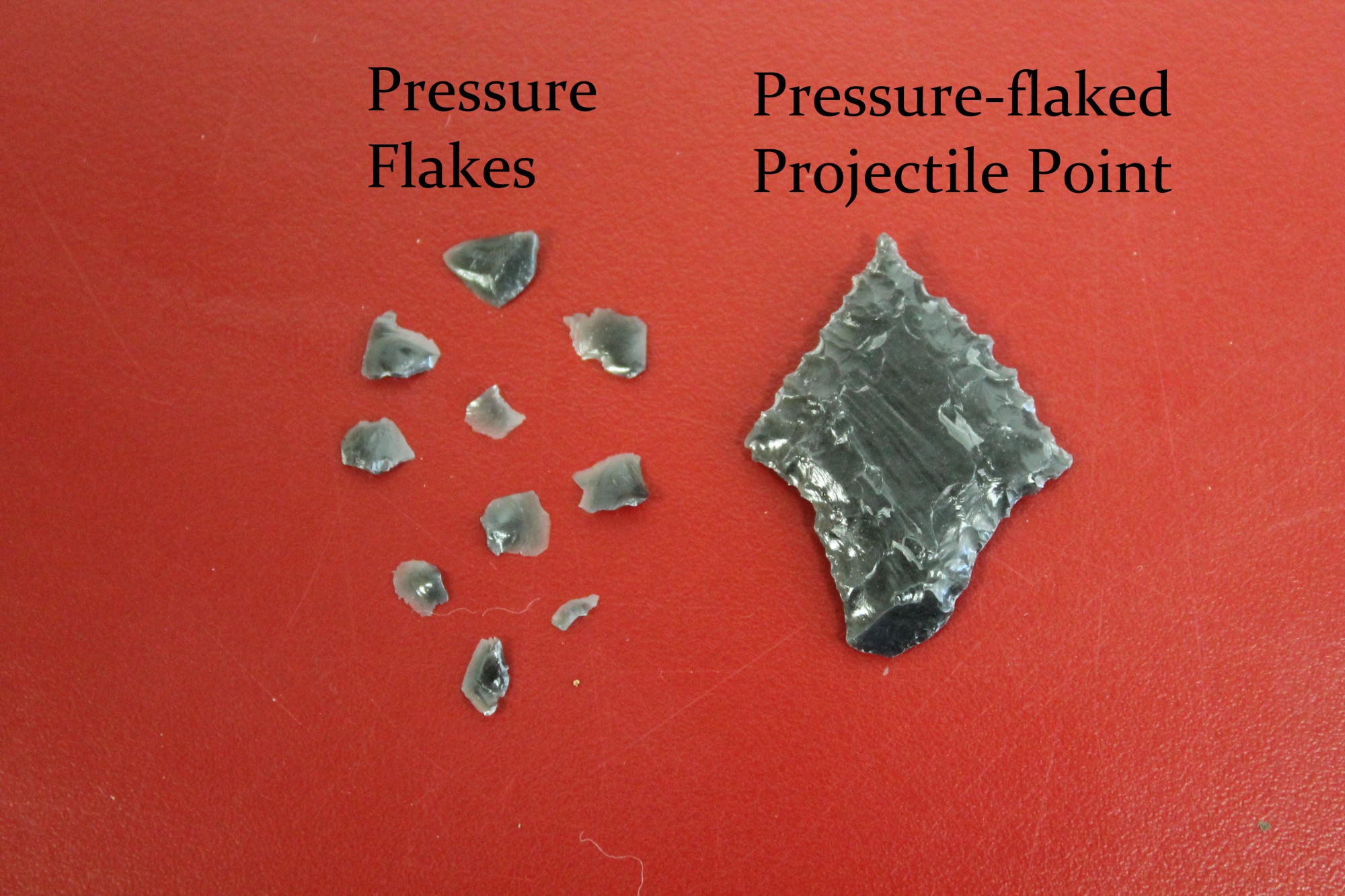

Pressure Flake

Knappers make pressure flakes by using an antler or copper tool to build up force on the edge of the nucleus. They then change the angle of the force to initiate material failure and remove the flake. Knappers make pressure flakes to sharpen the edges of bifaces and create notches for projectile points. Pressure flakes are often too small to be caught in the screens used in archaeological excavations.

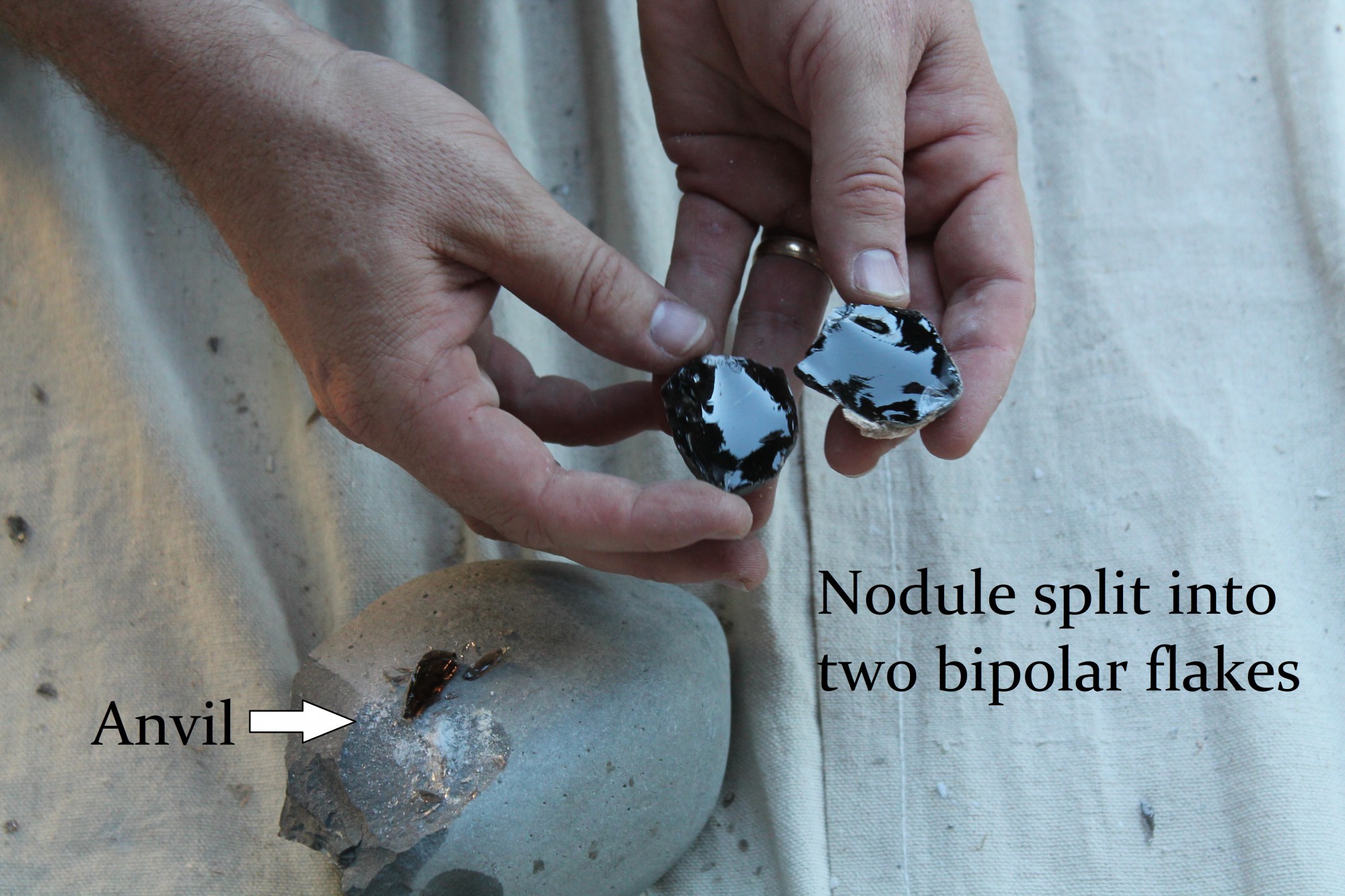

Bipolar Flakes

When knappers only have round nodules of knappable material that lack platforms of less than 90°, they often use bipolar flaking to split the nodules. In bipolar flaking, the knapper places the nodule on an anvil and breaks it with a hammer stone. The force of the anvil and hammer stone produce tight, concentric rings at platforms at both ends of the flake.

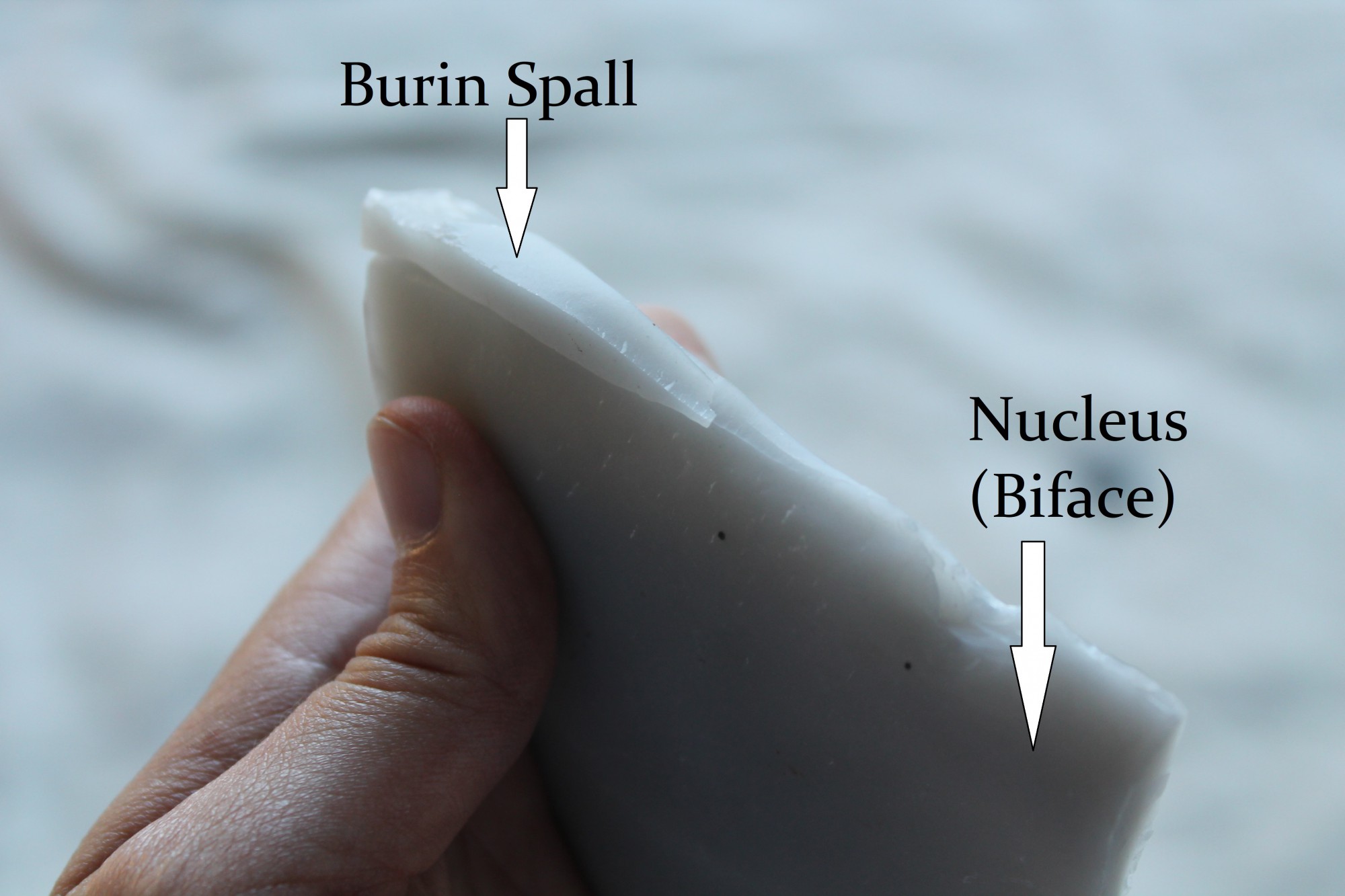

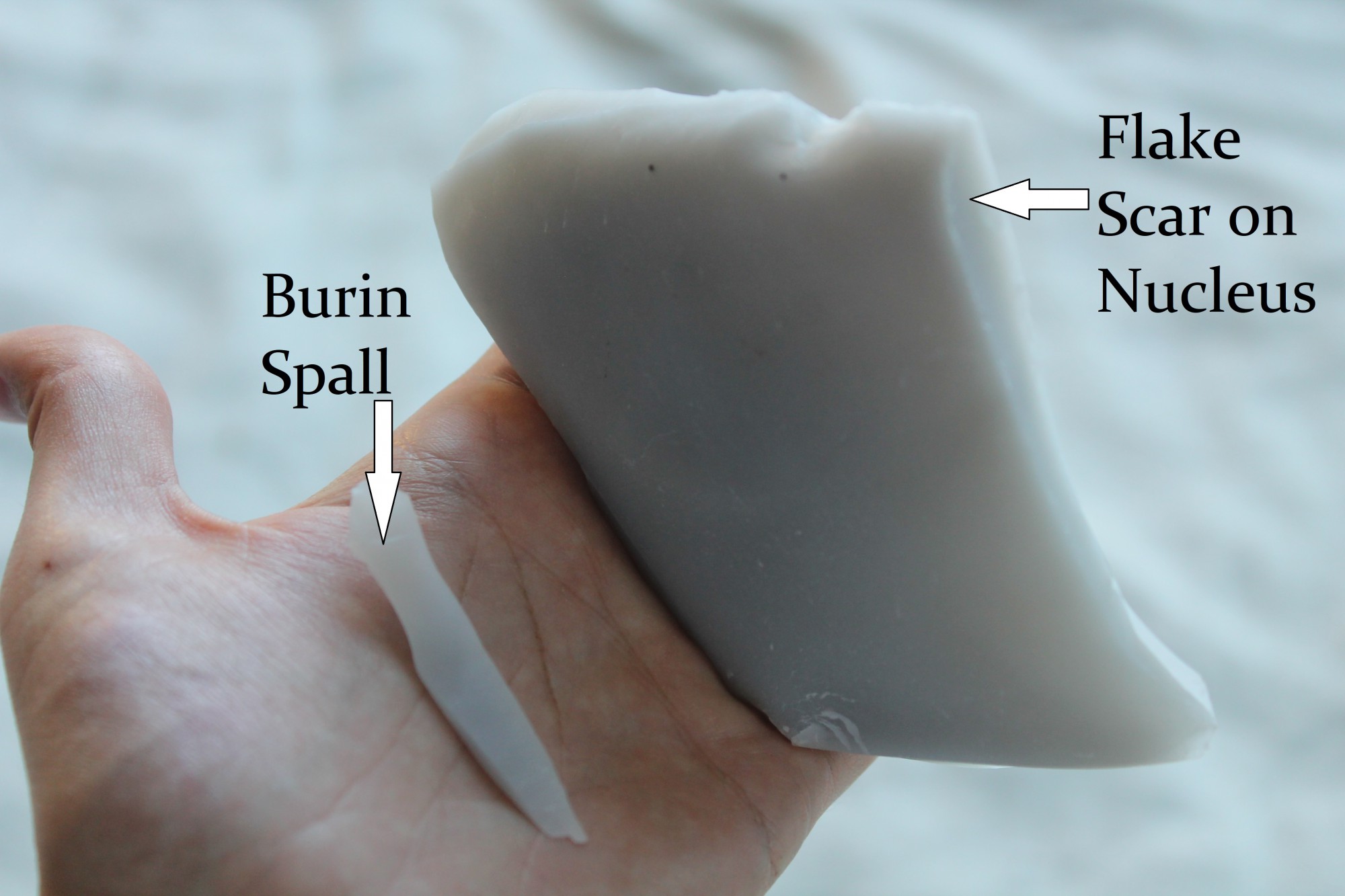

Burin Spalls

The knapper removes the straight edge of a biface to make a burin spall. Burin spalls can be made into drills.